Overcoming The Barriers Implementing Planograms

With all that is going on in the world at present the importance of ensuring you stock the right products that consumers want is now more important than ever, we already know the best way to manage your range is through the planogram process but implementing planogram changes (category resets) has always been a problem for many to get right.

Getting planograms implemented can be problematic

Planograms are essential for retailers to manage this process, however planogram implementation doesn’t always go the way their creators intended, incorrect sizes, out of date planograms, or even the wrong planogram may have been printed out, worse still it may have been implemented!. When this happens either the store manager or the category partner may have to deal with the fallout which could end up harming the relationship between store managers, suppliers or category managers.

Using good data to back up your planogram is essential

Creating a planogram without good data is like building a house without a foundation: It’s all going to come crashing down. You need insights into foot traffic, strong performers, customer preferences, retail trends, etc. to design an impactful planogram. The strategies that are ‘built into’ the planogram will most likely not be seen by the majority of end users but its success or failure will be remembered and could lead to resistance to future category resets if performance is poor.

Don’t over complicate the process, focus on the big wins

Planograms can very quickly become overcomplicated, category managers may need to deal with many different objectives, these could include brand or category objectives and may even be tied into supplier or retailer KPI’s. To get better ‘buy in’ at store level it’s best not to take on too much change at any one time, a staggered approach focusing on the ‘big wins’ will stand a better chance of being implemented, then after an agreed amount of time another smaller changes could be implemented, it’s better to phase in your changes.

So why do planograms often fail to get implemented?

A lot of time and effort goes into the creation of a good planogram, but all too often we overlook the people who are actually tasked with implementing them! There are a number of reasons why this happens but the most common ones are usually related to communication problems;

- I didn’t know about the planogram, “nobody told me there was a new planogram”

- Emails end up not being read or end up being lost in the long list of daily emails

- Staff are not sure which version planogram they should be implementing

- The printer is not working or has run out of paper or ink

- The planograms are often printed on B&W printers that may be difficult to read

- It can be difficult to get feedback on what has worked or not worked

- Access to planograms is limited and depends on getting access to a printed copy

Needless to say retailers can’t afford to blindly put their faith in their store managers to execute planograms, they must routinely check that stores are adhering to planogram and supplier agreements e.g. agreed facings, share of space, listings etc.

But there is a solution available that greatly increases the success rate

It’s not difficult to see why implementation can be problematic, it’s often the case that too much time is invested at the creation stage and not enough time is allocated to implementation, it then becomes a last minute dash to get things organised with staff or merchandisers, which is ironic as this is the most important part of the whole process!

The fix is simpler than you think, if you take away the two biggest blockers i.e. getting the right planogram to the right people and some way of receiving feedback on what has worked/not worked the success rate is greatly improved!

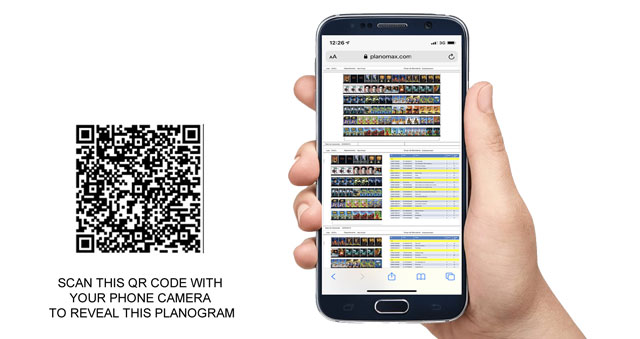

The Planomax solution allows planogram creators to upload planograms including instructions via a web portal, it also generates a simple QR code which can be easily printed or delivered to a digital SEL which is then read by any mobile phone or tablet with internet access. This allows anyone with access to view the correct planogram on their mobile device, it also allows registered users to feedback into the process (through the mobile app) which closes the loop and enables the creators to track the whole process.

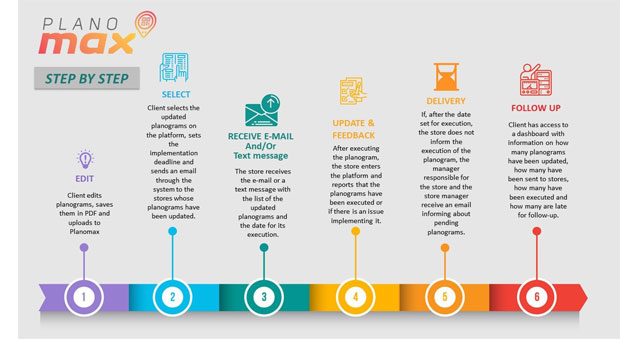

How the planomax process works;

(note planomax will work with any planogram tool as it only requires pdf files)

Getting the right information to the right people in a way that reduces cost, increases efficiency and also has an added advantage on the environment by reducing waste has to be a winner!

If you would like to know more about this very cool solution, please drop me a note gerry@shelfstock.ie or visit https://shelfstock.ie/planomax/